Wire rope lubricators, cleaners for wire as well as other modern tools are vital in the complicated field of maintenance for cables. Precision and longevity is crucial. These innovative devices play a pivotal role in ensuring the smooth operation and longer life of cables throughout various industries. This article examines the role of wire rope cleaners as well as oil lubricators in maintaining cables. We also examine their benefits and roles. For more information, click Wire Rope Lubricator

Understanding how to lubricate wire rope

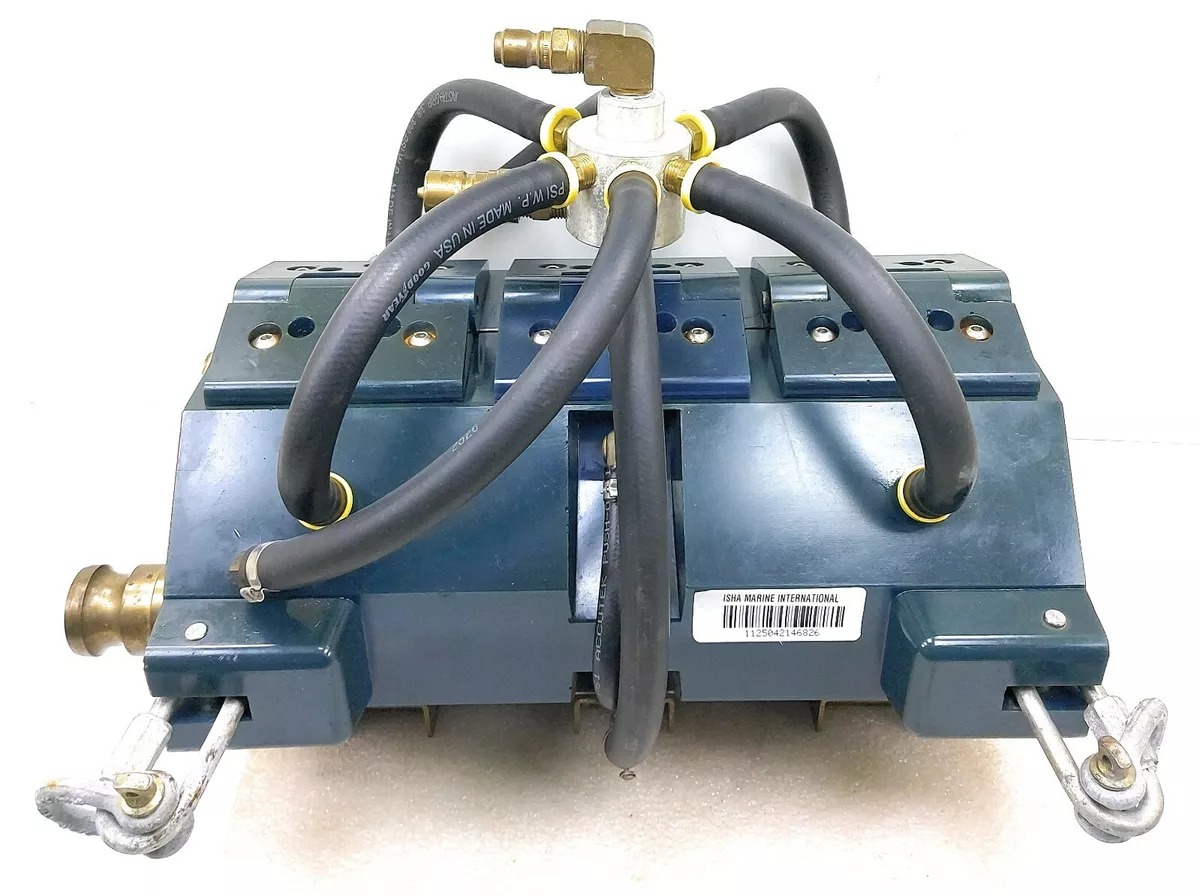

Wire rope lubricators are also known as wire rope lubricators are special tools that apply grease to the ropes in a methodical manner. This is vital for stopping corrosion, reducing friction, and enhancing the durability of the cable. The lubricator makes sure that the lubricating substances are evenly distributed across the length of the wire ropes, safeguarding them from wear and tear.

How to maintain cables by cleaning them with wire cleaners

Cleaners for wires and cables are both vital to maintain clean cables. These cleaners are created to get rid of contaminants, fluids and other debris that could get on cables during various processes. Wire cleaners are crucial when working in harsh environments where cables are exposed to extreme conditions. They ensure optimal performance and help prevent damage.

Optimizing Cable Lifespan:

Wire lubricators as well as wire cleaners used together can significantly extend the life of cables. Through the systematic application of lubrication using wire rope lubricators as well as removing pollutants with wire cleaners the cables are shielded from the harmful results of corrosion, friction and other external elements. The cable’s integrity is preserved with the result of improved efficiency in operation and lower maintenance costs.

Application of efficiency:

Wire Rope Lubricators were designed to be user-friendly and efficient in their application. They can be utilized on many different types and sizes wire ropes. They offer a variety of options in cable maintenance practices. Automated and systematic lubrication eliminates the risk of a poor applications that manual techniques can create.

Adaptability to Challenging Environments

Lubricators for wire ropes, and wire cleaners, are especially essential in the industries where cables have to endure tough conditions like the ones used in drilling, construction or maritime operations. They are made to withstand extreme conditions and provide reliable cable maintenance tools in a variety of settings.

Cost-Effective Maintenance Solutions:

An approach that is proactive to the care of cables using wire rope cleaners and lubricators, is a more cost-effective solution over the long run. The initial cost of these advanced tools pales against the potential cost of replacing cables along with downtime and costly repairs that result from ignoring proper maintenance procedures.

Conclusion:

In conclusion wire rope lubricators and wire cleaners serve as guardians of cable integrity, making sure that they are durable, precise and maximum performance in diverse industries. The systematic lubrication and removal of contaminants reduces costs for maintenance, as well as increases efficiency in operation. In a field that depends on cables to conduct vital processes, investing in advanced tools for maintaining cables such as wire rope lubricators, or wire cleaners isn’t just a wise choice, it’s is also essential.