Industrial robotics and robots have become key innovations and efficiency drivers in today’s ever-changing manufacturing landscape. The integration of robotics in manufacturing has revolutionized this sector. It has a myriad of advantages to companies seeking to improve productivity quality, competitiveness, or quality. Manufacturing robots will play a growing part in shaping the future of manufacturing as the demand for automated solutions increases.

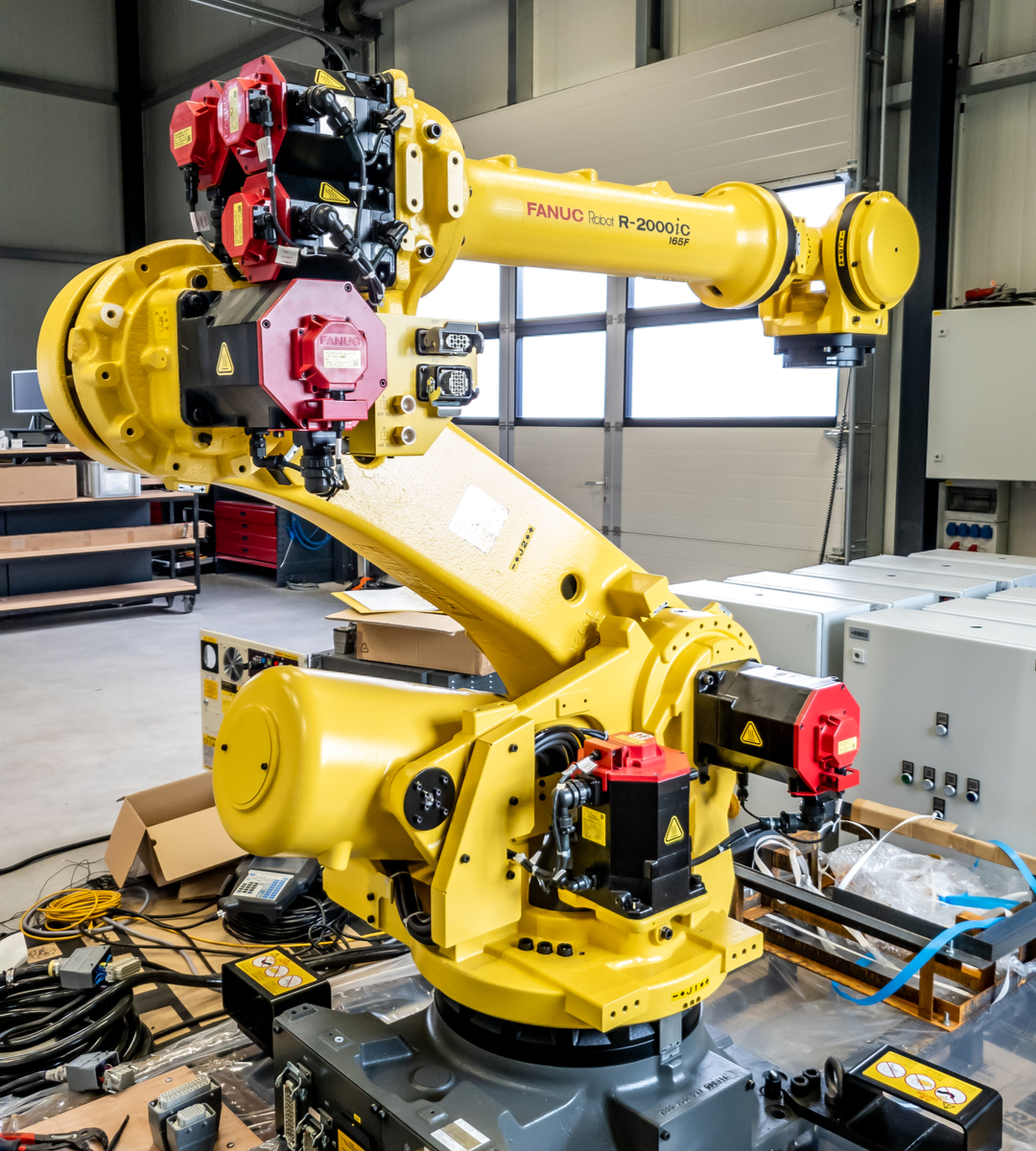

Manufacturing robots, also known as industrial robots are machines made to carry out various tasks within the manufacturing process. These tasks may include welding and painting, assembly, picking and putting, packaging and many more. Industrial robotics is an area that studies and uses these robots to maximize efficiency and precision in manufacturing processes.

One company at the forefront of this new era is Automated Solutions Australia (ASA), which specializes in designing industrial robots to offer flexible automation solutions to manufacturing clients. ASA robotics for manufacturing in industrial settings are designed to help clients achieve an advantage in their market by increasing their productivity and quality. ASA’s industrial robotic solutions that are built on best practices and the importance of quality, are utilized by businesses in a variety of industries including pharmaceuticals, automotive, electronics and more.

The benefits of implementing industrial robots in manufacturing are multifaceted. Efficiency and productivity is among the main benefits. Industrial robots can complete repetitive tasks with precision and consistency. This results in higher output rates and reduced cycles. It not only increases productivity, but it assists businesses in meeting the ever-growing demands of customers.

Industrial robots also help in improved quality control in manufacturing processes. These machines reduce the risk of errors by executing tasks with precision and reliability which results in better quality products. The result is increased customer satisfaction, as well as the credibility of a company that provides high-quality goods.

Industrial robots offer not only high-quality and efficiency, but also cost-saving benefits. While the initial investment in manufacturing robots may seem substantial However, the savings in the long run are substantial. Businesses can reduce operational costs by streamlining processes, and reduce manual labor. Industrial robots are able to work 24 hours a day making the most efficient use of resources, as well as reducing costs of production per unit.

Industrial robots can have an positive effect on the environment at work. They produce very low levels of noise, resulting in an environment that is more peaceful and more comfortable for workers. Their precision and speed also help to create a safer workplace in reducing the dangers of accidents and injuries that can be caused by manual working.

The incorporation of industrial robots plays an important role in the creation of jobs as well as the future job. Industrial robots are able to provide new opportunities for employment, despite fears that automation could take over human workers. These opportunities include roles in robot programming, maintenance, supervision, and oversight, as well and the development of novel technologies to support robotic manufacturing.

Businesses across a variety of industries continue to reap the benefits of industrial robots as the manufacturing sector continues to adopt the technology, it’s rapidly changing the manufacturing industry. Industrial robotics has the ability to increase efficiency, cost effectiveness and quality. It is revolutionizing the industry of manufacturing and setting new standards of excellence.

In the end, robots for manufacturing are a brand new way of manufacturing. The integration of these advanced technologies allows businesses to attain unprecedented levels of productivity, precision, and competitiveness. Industrial robots are expected to play a major function as the need for automation continues to grow. They will help in shaping the future of manufacturing and drive forward the development of technology.

The Benefits Of Industrial Robotics For Your Manufacturing Business

Industrial robotics and robots have become key innovations and efficiency drivers in today’s ever-changing manufacturing landscape. The integration of robotics in manufacturing has revolutionized this sector. It has a myriad of advantages to companies seeking to improve productivity quality, competitiveness, or quality. Manufacturing robots will play a growing part in shaping the future of manufacturing as the demand for automated solutions increases.

Manufacturing robots, also known as industrial robots are machines made to carry out various tasks within the manufacturing process. These tasks may include welding and painting, assembly, picking and putting, packaging and many more. Industrial robotics is an area that studies and uses these robots to maximize efficiency and precision in manufacturing processes.

One company at the forefront of this new era is Automated Solutions Australia (ASA), which specializes in designing industrial robots to offer flexible automation solutions to manufacturing clients. ASA robotics for manufacturing in industrial settings are designed to help clients achieve an advantage in their market by increasing their productivity and quality. ASA’s industrial robotic solutions that are built on best practices and the importance of quality, are utilized by businesses in a variety of industries including pharmaceuticals, automotive, electronics and more.

The benefits of implementing industrial robots in manufacturing are multifaceted. Efficiency and productivity is among the main benefits. Industrial robots can complete repetitive tasks with precision and consistency. This results in higher output rates and reduced cycles. It not only increases productivity, but it assists businesses in meeting the ever-growing demands of customers.

Industrial robots also help in improved quality control in manufacturing processes. These machines reduce the risk of errors by executing tasks with precision and reliability which results in better quality products. The result is increased customer satisfaction, as well as the credibility of a company that provides high-quality goods.

Industrial robots offer not only high-quality and efficiency, but also cost-saving benefits. While the initial investment in manufacturing robots may seem substantial However, the savings in the long run are substantial. Businesses can reduce operational costs by streamlining processes, and reduce manual labor. Industrial robots are able to work 24 hours a day making the most efficient use of resources, as well as reducing costs of production per unit.

Industrial robots can have an positive effect on the environment at work. They produce very low levels of noise, resulting in an environment that is more peaceful and more comfortable for workers. Their precision and speed also help to create a safer workplace in reducing the dangers of accidents and injuries that can be caused by manual working.

The incorporation of industrial robots plays an important role in the creation of jobs as well as the future job. Industrial robots are able to provide new opportunities for employment, despite fears that automation could take over human workers. These opportunities include roles in robot programming, maintenance, supervision, and oversight, as well and the development of novel technologies to support robotic manufacturing.

Businesses across a variety of industries continue to reap the benefits of industrial robots as the manufacturing sector continues to adopt the technology, it’s rapidly changing the manufacturing industry. Industrial robotics has the ability to increase efficiency, cost effectiveness and quality. It is revolutionizing the industry of manufacturing and setting new standards of excellence.

In the end, robots for manufacturing are a brand new way of manufacturing. The integration of these advanced technologies allows businesses to attain unprecedented levels of productivity, precision, and competitiveness. Industrial robots are expected to play a major function as the need for automation continues to grow. They will help in shaping the future of manufacturing and drive forward the development of technology.

Never miss any important news. Subscribe to our newsletter.

Related News

Avoiding Fire Hazards: The Case For Routine Air Duct Cleaning Service

Laval’s Best Practices For Air Duct Maintenance: Keeping Your Home Safe

How Often Should You Clean Your Air Ducts? A Guide For Laval Homeowners

Built For Speed, Secured For Peace Of Mind: Inter.Link’s DDoS-Protected Transit

Beyond The Berry: Unveiling The Acai Bowl’s Creamy Secret

Optimizing Your Budget: Strategies For Managing IP Transit Costs

IP Transit Costs: What You Should Expect And How To Plan For Them

Optimizing Your Budget: Strategies For Managing IP Transit Costs

Long Distance, Short Worries: Why Choose Simple Moving For Your Big Move

The Foresight Advantage: Competitive Intelligence For Strategic Business Planning

Revolutionize Your Network: Inter.Link’s API-Driven Provisioning

From Flower To Concentrate: How Oil Burner Pipes Change The Game